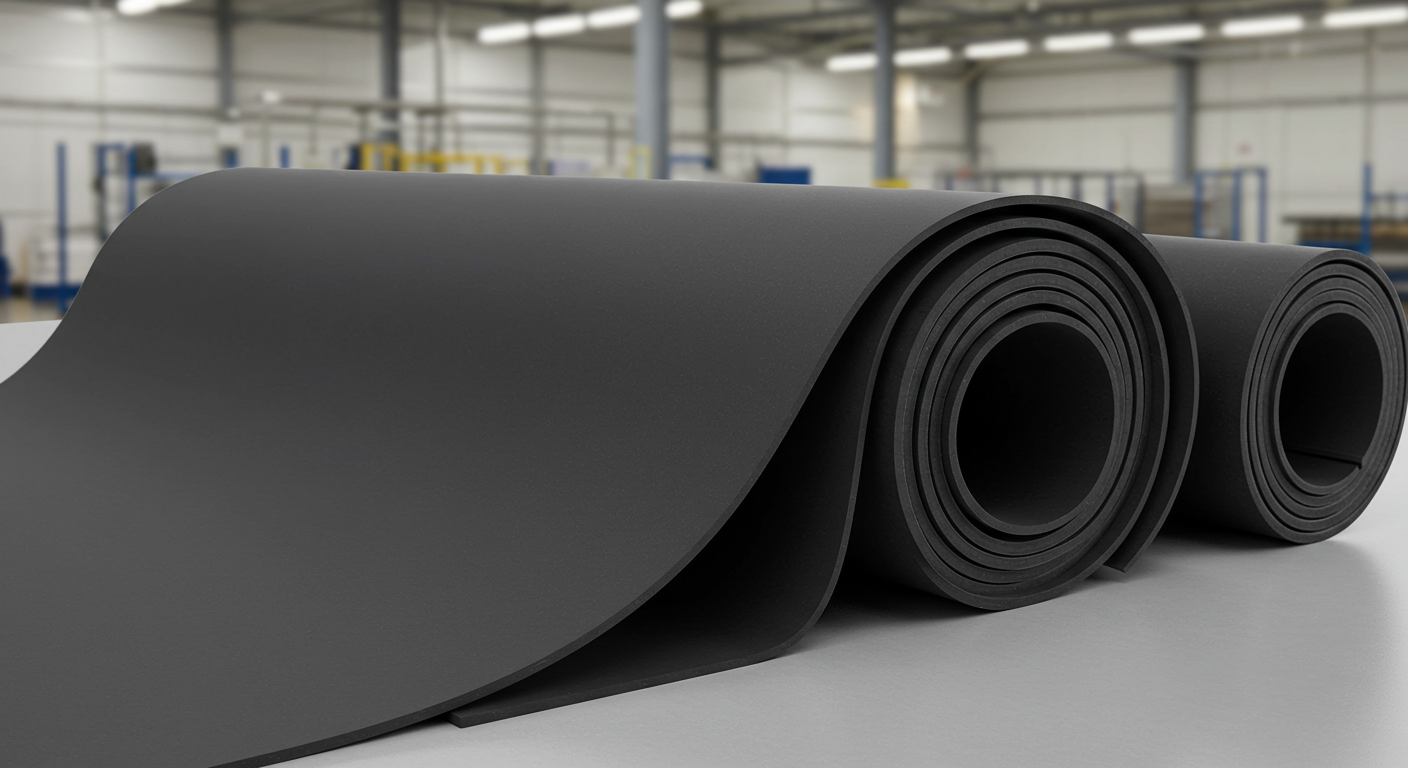

C411 M Rubber Material Dynasol is a highly regarded material in the rubber fabrics category, playing a crucial role across various industries by offering flexibility, durability, and resistance to extreme conditions. Known for its superior performance, it excels in packaging applications that demand strength and reliability. A common question about this fabric is: What is the melt factor of C411 M Rubber Material Dynasol?

This article explores the key properties of this material, its role in high-performance packaging, and the science behind its heat resistance. C411 M Rubber Material Dynasol is engineered to withstand high temperatures without losing its integrity, making it an excellent choice for industrial and commercial uses. Its composition ensures optimal thermal stability, flexibility, and long-term durability, setting it apart from conventional rubber materials.

With advancements in rubber technology, this material continues to evolve, meeting the growing demands of modern industries. Whether used in high-heat environments or applications requiring enhanced structural integrity, it remains a top choice due to its exceptional mechanical properties and resistance to deformation under stress.

C411 M Rubber Material by Dynasol: An Overview

C411 M Rubber Material Dynasol is a high-performance synthetic rubber known for its exceptional elasticity, durability, and heat resistance. Manufactured by Dynasol, a global leader in elastomers, this rubber is widely used in automotive, industrial, and manufacturing applications.

Its advanced formulation makes it adaptable to extreme heat and cold conditions, ensuring long-lasting performance across various industries.

When discussing the C411 M Rubber Material Dynasol, it is important to understand its thermal behavior. Unlike crystalline solids, rubber does not have a fixed melting point. Instead, it softens over a temperature range, gradually transitioning from a solid to a more flexible, viscous state when exposed to heat. Recent advancements in polymer science have introduced heat stabilizers and additives that enhance its thermal resistance, making it even more reliable for high-temperature environments.

Thermal Properties of C411 M Elastic Material by Dynasol

C411 M Rubber Material Dynasol is a specialized synthetic rubber known for its superior elasticity, strength, and heat resistance. Manufactured by Dynasol, a global leader in high-performance elastomers, this rubber is widely utilized in the automotive, industrial, and manufacturing sectors. Its advanced composition allows it to perform efficiently in extreme heat and cold conditions, making it a versatile choice for demanding applications.

Melting Point and Heat Resistance

When discussing the C411 M Rubber Material Dynasol, it’s important to note that rubber does not have a defined melting point like crystalline solids. Instead, it undergoes a softening phase, transitioning from a solid to a flexible, viscous state when subjected to heat. Modern advancements in polymer technology have introduced thermal stabilizers, enhancing its resistance to high temperatures and extending its lifespan in extreme environments.

One of the major advantages of C411 M Rubber Material Dynasol is its high heat resistance, ensuring durability in applications where conventional materials might fail. Its flexibility and tensile strength make it an excellent choice for dynamic packaging solutions, where both stability and adaptability are crucial.

Additionally, this rubber exhibits strong chemical resistance, making it ideal for industries dealing with oils, solvents, and harsh chemical exposure. Its ability to withstand chemical degradation ensures long-lasting performance in challenging environments, including automotive seals, industrial gaskets, and specialized coating.

Sustainability and Environmental Impact of C411 M Rubber Material Dynasol

In today’s world, sustainability plays a crucial role in material selection. Dynasol, the manufacturer of C411 M Rubber Material Dynasol, has adopted eco-friendly manufacturing practices, ensuring minimal environmental impact. This synthetic rubber is recyclable, reducing industrial waste and contributing to sustainable commercial applications. Additionally, advancements in green production technology have enhanced its energy efficiency during processing, making it an environmentally responsible choice for industries.

Melting Point and Thermal Stability

For those exploring the melting factor of C411 M Rubber Material Dynasol, it is important to understand that rubber does not have a precise melting point like metals or crystalline solids. Instead, it undergoes a softening phase, where it transitions from a solid to a more flexible, viscous state under heat. A key benefit of this material is its thermal stability, which not only prevents premature degradation but also minimizes the release of harmful emissions, reinforcing its eco-friendly properties.

By combining durability, recyclability, and thermal resistance, C411 M Rubber Material Dynasol has become a preferred choice in automotive, industrial, and environmental applications, offering both high performance and sustainability.

Outstanding Durability of Dynasol’s C411 M Rubber Material Under High-Stress Conditions

One of the standout features of C411 M Rubber Material Dynasol is its exceptional resistance to extreme pressure and mechanical stress. Whether exposed to intense load-bearing conditions, continuous movement, or rapid temperature shifts, this high-performance synthetic rubber has strength and flexibility without significant degradation.

This makes C411 M Rubber Material Dynasol an ideal choice for industries that demand superior durability, such as heavy machinery, manufacturing, and automotive applications. Its ability to maintain structural integrity under harsh environments and reliability, efficiency, and lifespan. Recent advancements in rubber engineering have further improved its tensile strength and fatigue resistance, ensuring optimal performance even in the most demanding industrial settings.

Dynasol’s C411 M Rubber Material: Driving Innovations in Advanced Manufacturing

Modern technological advancements demand materials that can adapt to evolving challenges, and C411 M Rubber Material Dynasol has become a cornerstone of next-generation engineering solutions. Its compatibility with cutting-edge manufacturing techniques, such as injection molding, extrusion, and compression molding, enables the production of custom-designed components with exceptional precision and durability.

The versatility of C411 M Rubber Material Dynasol allows engineers to develop high-performance parts facing industrial, automotive, and aerospace applications. Its superior elasticity, chemical resistance, and thermal stability make it an ideal choice for demanding environments where strength and flexibility are equally crucial. Additionally, recent advancements in polymer science have enhanced its UV and oxidation resistance, further extending its operational lifespan and reliability.

The extensive use of C411 M Rubber Material Dynasol across multiple industries highlights its exceptional adaptability and reliability. From automotive manufacturers requiring high-performance seals and gaskets to the healthcare sector needing hypoallergenic, heat-resistant, and non-toxic materials, this advanced synthetic rubber meets diverse demands with remarkable efficiency.

The consistent durability and superior mechanical properties of C411 M Rubber Material Dynasol ensure optimal performance in both small-scale applications and large-scale industrial operations. Its resistance to harsh chemicals, extreme temperatures, and mechanical wear makes it an indispensable material in the construction, aerospace, and energy sectors. Recent developments in elastomer technology have further enhanced its UV resistance and sustainability, solidifying its position as a preferred choice for cutting-edge engineering and manufacturing solutions.

The Evolving Role of Dynasol’s C411 M Rubber Material in Advanced Industries

The potential applications of C411 M Rubber Material Dynasol are continuously expanding as advancements in material science and polymer engineering improve performance and durability. With ongoing innovations, its composition and properties are being further refined, making it an even more valuable asset in emerging sectors such as renewable energy, aerospace, and high-tech manufacturing.

As industries shift toward sustainability and energy efficiency, C411 M Rubber Material Dynasol is set to play a pivotal role in shaping the next generation of high-performance materials. Its enhanced thermal resistance, chemical stability, and recyclability make it an eco-friendly solution for companies seeking long-lasting, high-efficiency materials. With growing demand for electric vehicles, wind turbine components, and aerospace insulation, this versatile rubber is positioned to drive technological advancements across multiple industries.

Frequently asked questions

-

What is C411 M Rubber Material Dynasol?

- C411 M is a specialized synthetic rubber produced by Dynasol, known for its exceptional elasticity, strength, and heat resistance.

-

What are the primary applications of C411 M Rubber Material Dynasol?

- This material is widely used in industries such as automotive, manufacturing, and packaging, particularly in applications requiring high performance and reliability.

-

What is the melting point of C411 M Rubber Material Dynasol?

- C411 M doesn’t have a sharp melting point. Instead, it exhibits a softening range between 150°C and 200°C, depending on its specific formulation.

-

How does C411 M Rubber Material Dynasol perform under extreme temperatures?

- It maintains its properties under a wide temperature range, making it suitable for applications involving severe heat and cold environments.

-

Is C411 M Rubber Material Dynasol resistant to chemicals?

- Yes, it offers excellent resistance to oils, solvents, and various aggressive chemicals, enhancing its durability in harsh environments.

-

What are the environmental impacts of using C411 M Rubber Material Dynasol?

- Dynasol incorporates environmentally friendly practices in manufacturing C411 M, and the material is recyclable, contributing to waste reduction in industrial applications.

-

Where can I find technical and safety data sheets for C411 M Rubber Material Dynasol?

Conclusion

The C411 M Rubber Material Dynasol is known for its exceptional heat resistance and durability, making it a top choice for industries requiring high-performance rubber solutions. While this material has no distinct melting point, it can withstand temperatures up to 250°C, ensuring reliable performance in demanding applications.

From automotive and construction to industrial manufacturing, C411 M Rubber Material Dynasol stands out due to its resilience, flexibility, and long-term stability. Its ability to endure extreme conditions without losing its mechanical properties makes it ideal for high-stress environments.

For businesses and manufacturers researching advanced rubber materials, this high-performance compound offers superior thermal resistance, strength, and adaptability. With its exceptional heat tolerance and durability, it is a smart investment for applications requiring long-lasting and efficient rubber solutions.