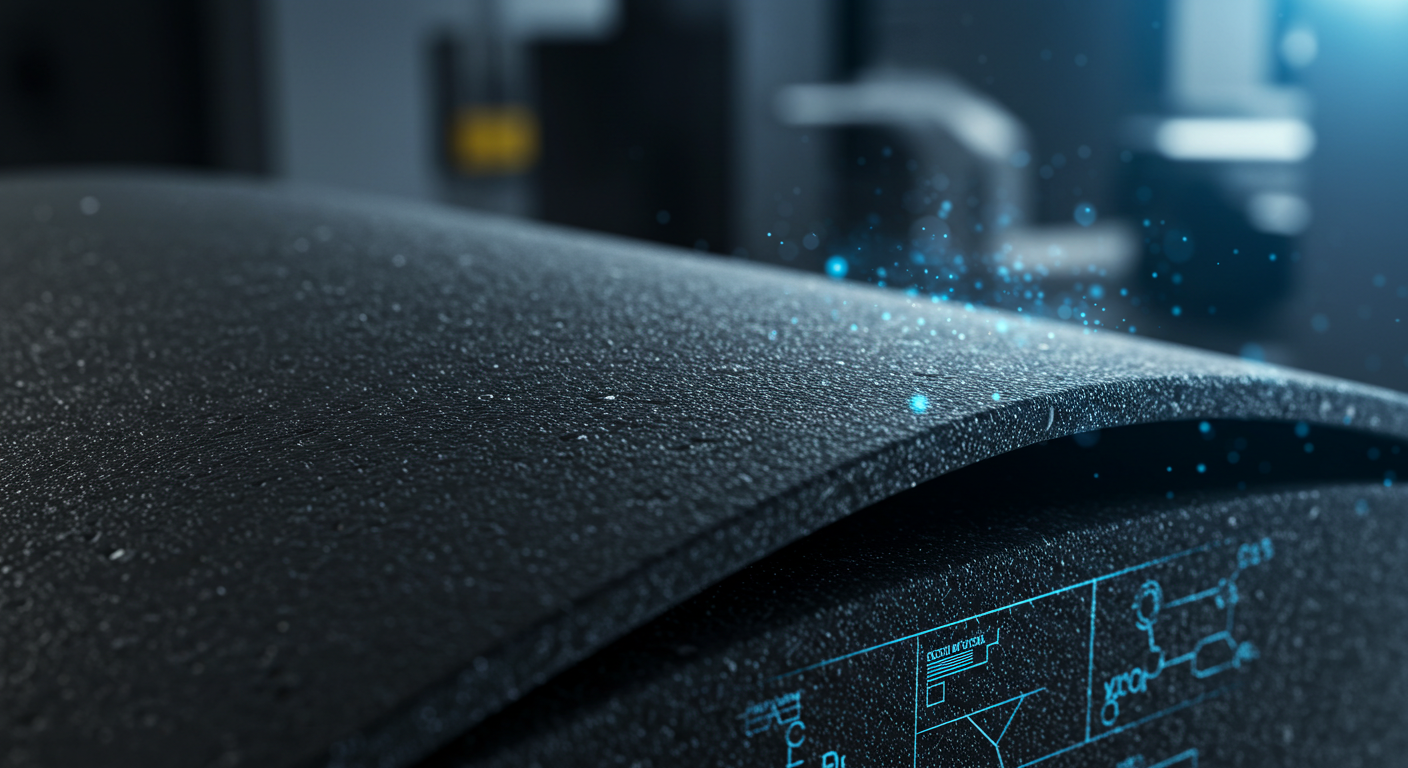

Rubber fabrics play a crucial role in various industries due to their flexibility, durability, and resistance to extreme conditions. One of the most reliable options in this category is C411 M Rubber Material Dynasol, widely recognized for its superior performance in packaging applications that demand high strength and longevity.

A common question about this material is: What is the melt factor of C411 M Rubber Material Dynasol? Understanding its thermal properties is essential for industries relying on heat-resistant materials. This article delves into the key characteristics of this rubber fabric, including its composition, packaging applications, and the science behind its heat conduction.

With advancements in polymer technology, C411 M Rubber Material Dynasol continues to be a preferred choice for industries requiring high-performance elastomers. Whether used in protective packaging, industrial applications, or specialized coatings, this material stands out due to its enhanced resistance to temperature variations and mechanical stress.

Understanding Dynasol C411 M Rubber Material: Properties and Applications

C411 M Rubber Material Dynasol is a high-performance synthetic rubber known for its exceptional elasticity, durability, and resistance to heat. Manufactured by Dynasol, a global leader in elastomer production, this rubber material is widely used across industries such as automotive, construction, and industrial manufacturing. Its advanced formulation ensures outstanding performance in extreme temperatures, making it suitable for both high-heat and freezing environments, which enhances its adaptability.

One frequently asked question about C411 M Rubber Material Dynasol is: What is its melting factor? Unlike crystalline solids, rubber materials do not have a distinct melting point. Instead, they undergo a softening phase, gradually transitioning from solid to a more flexible, viscous state when exposed to heat. This unique thermal behavior makes it ideal for applications that require flexibility and heat resistance.

With continuous advancements in rubber technology, C411 M Rubber Material Dynasol remains a top choice for industries needing reliable, heat-resistant, and high-strength elastomers. Its versatility and superior properties make it essential for applications demanding long-term durability and performance.

C411 M Rubber Material Dynasol is a specialized synthetic rubber known for its exceptional elasticity, durability, and heat resistance. Produced by Dynasol, a leading manufacturer of high-performance elastomers, this material is widely used in the automotive, construction, and industrial manufacturing sectors. Its advanced formulation allows it to withstand extreme temperatures, making it highly adaptable for both high-heat and freezing conditions.

What is the Melting Factor of C411 M Rubber Material Dynasol?

When discussing the thermal properties of C411 M Rubber Material Dynasol, it’s crucial to understand that rubber materials do not have a distinct melting point like crystalline solids. Instead, they soften gradually over a temperature range, transitioning from a solid to a more flexible, viscous state. This controlled softening makes it ideal for applications requiring high heat resistance and flexibility.

Advantages of Using C411 M Rubber Material Dynasol

One of the key benefits of C411 M Rubber Material Dynasol is its superior heat resistance, ensuring long-term durability in applications where other materials might degrade or fail. Its excellent tensile strength and elasticity make it an ideal choice for dynamic packaging solutions where both flexibility and structural integrity are essential.

Another significant advantage is its resistance to chemical degradation. C411 M Rubber Material Dynasol is designed to withstand exposure to oils, solvents, and other harsh chemicals, making it a reliable material for use in industries where chemical resistance is a priority.

With continuous innovations in rubber technology, C411 M Rubber Material Dynasol remains a top choice for industries that require high-performance, heat-resistant, and chemically stable elastomers. Its versatility and durability make it an essential component in applications demanding long-lasting performance.

In today’s world, sustainability plays a crucial role in material selection. Dynasol, the manufacturer of C411 M Rubber Material Dynasol, has integrated eco-friendly practices into its production processes, ensuring that this high-performance rubber fabric is both durable and environmentally responsible. The material is recyclable, helping industries reduce waste and support sustainable commercial applications.

What is the Melting Factor of C411 M Rubber Material Dynasol?

For those exploring the thermal properties of C411 M Rubber Material Dynasol, it is important to note that rubber materials do not have a fixed melting point like crystalline solids. Instead, they gradually soften over a temperature range, transitioning from solid to a more flexible, viscous state.

A key advantage of C411 M Rubber Material Dynasol is its exceptional thermal stability, which minimizes harmful emissions during use. This feature enhances its environmental benefits, making it a sustainable choice for industries that prioritize both performance and eco-friendliness.

With continuous advancements in material science, C411 M Rubber Material Dynasol remains a top choice for applications requiring high heat resistance, durability, and reduced environmental impact. Its combination of strength, flexibility, and recyclability makes it a preferred option for industries seeking long-lasting and sustainable solutions.

C411 M Dynasol Rubber Material vs. Other Materials: A Comparison

When comparing C411 M Rubber Material Dynasol with other synthetic rubbers, its superior thermal and chemical resistance make it a standout choice. While natural rubber offers greater flexibility in extremely low temperatures, it falls short in high-temperature environments where C411 M Rubber Material Dynasol excels. Its advanced formulation ensures long-term durability and stability, even under the most demanding conditions.

Why Choose C411 M Rubber Material Dynasol?

Industries that require materials capable of withstanding extreme temperatures and harsh environments rely on C411 M Rubber Material Dynasol for its unmatched performance. Its ability to maintain structural integrity across a broad temperature range enhances reliability in critical applications such as automotive components, industrial seals, and heavy-duty packaging.

Moreover, C411 M Rubber Material Dynasol is engineered for exceptional resistance to oils, solvents, and harsh chemicals, making it an ideal choice for industries requiring high-performance elastomers. With ongoing advancements in rubber technology, this material continues to set the standard for durability, efficiency, and adaptability in various industrial applications.

Best Practices for Maximizing the Performance of C411 M Rubber Material Dynasol

When using C411 M Rubber Material Dynasol, it is vital to consider the specific conditions in which it will be applied. Ensuring the material operates within the recommended temperature range and chemical exposure limits significantly enhances its longevity and overall performance.

Additionally, regular inspection and maintenance, such as cleaning off contaminants and avoiding contact with harsh chemicals outside its tolerance levels, will help preserve its flexibility and strength. By following these best practices, industries can maximize the reliability and efficiency of C411 M Rubber Material Dynasol, making it a preferred choice for high-performance applications.

Durability Under High-Stress Conditions

One of the standout features of C411 M Rubber Material Dynasol is its exceptional resistance to extreme pressure and demanding conditions. Whether exposed to heavy mechanical stress, continuous movement, or fluctuating temperatures, this advanced rubber material maintains its integrity without significant wear or deterioration. Its robust composition ensures long-lasting performance, even in the most challenging industrial environments.

Why C411 M Rubber Material Dynasol Excels in High-Stress Applications

Industries that require materials capable of withstanding rigorous use, such as manufacturing, heavy machinery, and construction, highly value C411 M Rubber Material Dynasol for its durability. Unlike conventional rubber materials, it resists deformation and maintains structural strength, making it a reliable choice for critical applications.

Moreover, C411 M Rubber Material Dynasol offers superior elasticity and resistance to environmental factors such as heat, chemicals, and mechanical fatigue. These properties make it an indispensable material for industries seeking high-performance solutions that ensure longevity, reliability, and cost-efficiency in tough operating conditions.

Innovation demands materials that can adapt to evolving challenges, and C411 M Rubber Material Dynasol has become a fundamental component in modern engineering solutions. Its compatibility with cutting-edge manufacturing techniques, such as injection molding and extrusion, enables the creation of highly customized components tailored to specific industrial needs.

The Versatility of C411 M Rubber Material Dynasol in Advanced Manufacturing

One of the key advantages of C411 M Rubber Material Dynasol is its ability to support intricate designs without compromising strength or durability. Engineers can utilize its exceptional elasticity, heat resistance, and chemical stability to develop high-performance parts for automotive, aerospace, and industrial applications.

Additionally, the adaptability of C411 M Rubber Material Dynasol allows manufacturers to optimize production efficiency while ensuring cost-effective, long-lasting solutions. Its advanced formulation makes it an ideal material for industries seeking high-quality, precision-engineered components that can withstand extreme conditions and mechanical stress.

Widespread Market Potential

The extensive use of C411 M Rubber Material Dynasol across multiple industries highlights its exceptional versatility and dependability. From automotive manufacturers seeking long-lasting seals to healthcare companies requiring hypoallergenic, heat-resistant materials, this advanced rubber fabric meets diverse industrial demands with superior performance.

Why C411 M Rubber Material Dynasol Stands Out in Various Applications

The durability and adaptability of C411 M Rubber Material Dynasol make it an ideal choice for industries requiring high-performance materials. Its ability to withstand extreme temperatures, resist chemical exposure, and maintain flexibility ensures efficiency in both small-scale applications and large industrial projects.

Additionally, the reliability of C411 M Rubber Material Dynasol cements its status as a preferred material across different sectors. Whether in automotive, aerospace, medical, or heavy machinery industries, its consistent performance and advanced properties make it a top choice for engineers and manufacturers looking for durable, high-quality solutions.

The potential applications of C411 M Rubber Material Dynasol are set to expand as material science and technological advancements continue to evolve. With ongoing innovations, its formulation is expected to improve, further enhancing its durability, flexibility, and resistance to extreme conditions. These improvements will make C411 M Rubber Material Dynasol even more valuable in emerging industries such as renewable energy and aerospace, where high-performance materials are essential.

The Future of C411 M Rubber Material Dynasol in Advanced Industries

As industries shift toward sustainability and operational efficiency, C411 M Rubber Material Dynasol is positioned to play a crucial role in the development of eco-friendly and high-performance solutions. Its recyclability and reduced environmental impact make it a preferred choice for manufacturers striving to meet global sustainability standards.

With increasing demand for resilient materials in sectors like electric vehicles, wind energy, and space exploration, C411 M Rubber Material Dynasol is expected to become an integral part of next-generation engineering. Its continued adaptation and enhancement will solidify its status as a leading material in the future of industrial innovation.

Conclusion: Melting Point of Dynasol C411 M Rubber Material

The C411 M Rubber Material Dynasol is a high-performance polymer renowned for its exceptional thermal stability and versatility. Unlike materials with a sharp melting point, this rubber compound gradually softens within a range of 120–140°C (248–284°F)1, while its recommended maximum operating temperature is 125°C (257°F)1. This makes the C411 M Rubber Material Dynasol ideal for demanding applications in automotive, construction, and industrial sectors, where heat resistance and durability are critical.

Engineers favor this material for components like seals, gaskets, and vibration-dampening systems due to its ability to endure extreme temperatures without degrading13. Recent innovations highlight its use in eco-friendly formulations, aligning with sustainability goals by incorporating recycled materials3. Additionally, its chemical resistance and flexibility ensure reliable performance in harsh environments, from automotive engine parts to weatherproof construction sealants.

For industries prioritizing longevity and environmental responsibility, the C411 M Rubber Material Dynasol offers a balanced blend of thermal resilience (with softening starting around 100–130°C1) and modern sustainability. Its adaptability across high-temperature applications, coupled with ongoing advancements in polymer technology, solidifies its role as a top choice for innovative engineering solutions.